Negotiable

The date of payment from buyers deliver within days

Zhejiang

Long-term effective

2017-12-16 09:23

24

Company Profile

Company Profile

By certification [File Integrity]

Contact:Mr. Jacky Yang(Mr.)

Email:

Telephone:

Phone:

Area:Zhejiang

Address:Zhejiang

Website: http://bestmagnets.sddxkj398.com/

Best Magnets Advantages:

1. We have Strategic cooperation with rare earth mine, which enables us strong ability to control rare earth raw materials cost.

2. ISO9001, ISO14001 certified company, ROHS,SGS complied products.

3. More than 10 years experience of OEM service since 2004, VIP customers such as BOSCH, LG, PANASONIC

4. Over 1000 Tons of neodymium magnets delivered to Europe, America,Russia,South East Asia every year.

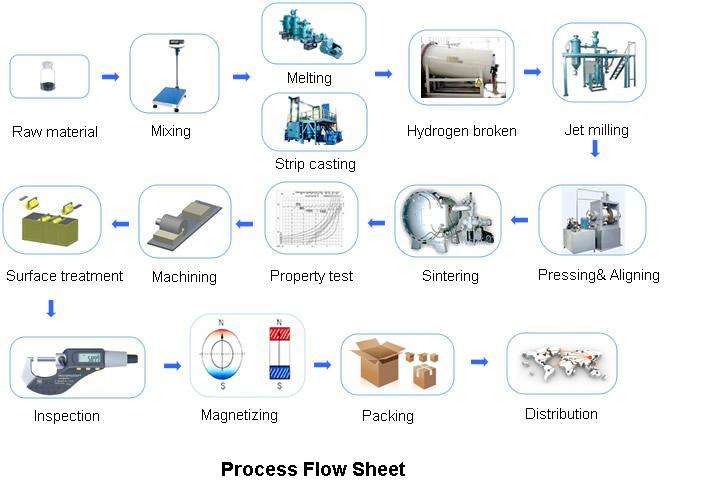

5. We have full lines of production equipments,from Sintering to Machining,then Coating to Magnetizing,which enables us to win 100% control on quality.

| Description | Sintered Rare Earth Magnets | |

| Material | Neodymium-Iron-Boron | |

| Working Temperature | Grade | Max. Operating Temperatures |

| N35-N52 | 80°C (176°F) | |

| 33M- 48M | 100°C (212°F) | |

| 33H-48H | 120°C (248°F) | |

| 30SH-45SH | 150°C (302°F) | |

| 30UH-40UH | 180°C (356°F) | |

| 28EH-38EH | 200°C (392°F) | |

| 28AH-35AH | 220°C (428°F) | |

| Magnet Shape | Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes and more. Customized shapes for Rare Earth Magnets are available. | |

| Magnet Coating | Ni-Cu-Ni, Nickel, Zn, Gold, Silver, Copper, Epoxy, Chemical, PTFE, Parylene, Everlube, Passivation and more. | |

| Technology Advantage | Depending on advanced R&D center, Quality control team and professional machining technicians, we can surpass our competitors in the stability of quality and superiority of property. | |

| Delivery Advantage | The lead time must be 3-5 days quicker than industry average because of more flexible machine process control. | |

| Price Advantage | The price is 5-8% cheaper than industry average because of an excellent and efficient management system. | |

| Application | Rare Earth Magnets are widely used in many fields, such as motors, sensors, microphones, wind turbines, wind generators, VCMs in hard disk drives, printer, switchboard, loudspeakers, magnetic separation, magnetic hooks, magnetic holder, magnetic chuck, common daily use, and so on. | |

|

Best Magnets Technology offers excellent selection of magnetic assembly, magnetic tool and magnetic equipment for home use, office use, industrial use, computer use and so on. Both our office and factory are located in Ningbo which is very developed city and very big seaport. We provides you an extensive range of magnetic assembly, magnetic tool and magnetic equipment. Containing our excellent original design, every product is elaborately produced by our factory. When you use them, you feel so comfortable and wonderful. These tools and assemblies are widely used in your daily life by helping you clean scrap iron and other debris, lift up heavy items and fix objects firmly. And they even have more functions you've never thought of. We appreciate your enquiry and we will give you incomparably good product and services. Welcome to be our distributor. The high quality of our products and the considerate after-sale service will make your business more and more prosperous. If you want to purchase magnetic assembly, magnetic tool and magnetic equipment, please feel free to contact us. | ||

| Some Coatings of Rare Earth Magnets: | ||||

| Surface | Coating | Thickness (Microns) | Color | Resistance |

| Passivation | 1 | Silver Grey | Temporary Protection | |

| Nickel | Ni+Ni | 10-20 | Bright Silver | Excellent against Humidity |

| Ni+Cu+Ni | ||||

| Zinc | Zn | 8-20 | Bright Blue | Good Against Salt Spray |

| C-Zn | Shinny Color | Excellent Against Salt Spray | ||

| Tin | Ni+Cu+Sn | 15-20 | Silver | Superior Against Humidity |

| Gold | Ni+Cu+Au | 10-20 | Gold | Superior Against Humidity |

| Copper | Ni+Cu | 10-20 | Gold | Temporary Protection |

| Epoxy | Epoxy | 15-25 | Black, Red, Grey | Excellent Against Humidity & Salt Spray |

| Ni+Cu+Epoxy | ||||

| Zn+Epoxy | ||||

| Chemical | Ni | 10-20 | Silver Grey | Excellent Against Humidity |

| Parylene | Parylene | 5-20 | Grey | Excellent Against Humidity, Salt Spray. Superior Against Solvents, Gases, Fungi and Bacteria. |

1.Full quality testing machines to ensure the high performance of qulified magnets.

2.We manufactur standard magnets strictly according to the standard GB/T 13560-2009,by inspection of material Br,Hcj,Hcb,BHmax,and fully as per customers' requirement of max working tempreture.

| Sintered NdFeB Magnet | |||||||||

| Grade | Residual Induction (Br) | Coercive Force (Hcb) | Intrinsic Coercive Force (Hcj) | Max Energy Product (BH)max | Max Working Temp. | ||||

| T | kGs | kA/m | kOe | kA/m | kOe | Kj/m³ | MGOe | (°C) | |

| N35 | 1.17-1.22 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80 |

| N38 | 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 80 |

| N40 | 1.25-1.28 | 12.5-12.8 | ≥907 | ≥11.4 | ≥955 | ≥12 | 302-326 | 38-41 | 80 |

| N42 | 1.28-1.32 | 12.8-13.2 | ≥915 | ≥11.5 | ≥955 | ≥12 | 318-342 | 40-43 | 80 |

| N45 | 1.32-1.38 | 13.2-13.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 342-366 | 43-46 | 80 |

| N48 | 1.38-1.42 | 13.8-14.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 366-390 | 46-49 | 80 |

| N50 | 1.40-1.45 | 14.0-14.5 | ≥796 | ≥10 | ≥876 | ≥11 | 374-406 | 47-51 | 60 |

| N52 | 1.43-1.48 | 14.3-14.8 | ≥796 | ≥10 | ≥876 | ≥11 | 390-422 | 49-53 | 60 |

| N35M | 1.17-1.22 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100 |

| N38M | 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 100 |

| N40M | 1.25-1.28 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 100 |

| N42M | 1.28-1.32 | 12.8-13.2 | ≥955 | ≥12 | ≥1114 | ≥14 | 318-342 | 40-43 | 100 |

| N45M | 1.32-1.38 | 13.2-13.8 | ≥955 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 100 |

| N48M | 1.37-1.43 | 13.7-14.3 | ≥1027 | ≥12.9 | ≥1114 | ≥14 | 366-390 | 46-49 | 100 |

| N50M | 1.40-1.45 | 14.0-14.5 | ≥1033 | ≥13 | ≥1114 | ≥14 | 382-406 | 48-51 | 100 |

| N35H | 1.17-1.22 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120 |

| N38H | 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥ 17 | 287-310 | 36-39 | 120 |

| N40H | 1.25-1.28 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 120 |

| N42H | 1.28-1.32 | 12.8-13.2 | ≥955 | ≥12 | ≥1353 | ≥17 | 318-342 | 40-43 | 120 |

| N45H | 1.32-1.36 | 13.2-13.6 | ≥963 | ≥12.1 | ≥1353 | ≥ 17 | 326-358 | 43-46 | 120 |

| N48H | 1.37-1.43 | 13.7-14.3 | ≥995 | ≥12.5 | ≥1353 | ≥17 | 366-390 | 46-49 | 120 |

| N35SH | 1.17-1.22 | 11.7-12.2 | ≥876 | ≥11 | ≥1592 | ≥20 | 263-287 | 33-36 | 150 |

| N38SH | 1.22-1.25 | 12.2-12.5 | ≥907 | ≥11.4 | ≥1592 | ≥20 | 287-310 | 36-39 | 150 |

| N40SH | 1.25-1.28 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 150 |

| N42SH | 1.28-1.32 | 12.8-13.2 | ≥987 | ≥12.4 | ≥1592 | ≥20 | 318-342 | 40-43 | 150 |

| N45SH | 1.32-1.38 | 13.2-13.8 | ≥1003 | ≥12.6 | ≥1592 | ≥20 | 342-366 | 43-46 | 150 |

| N28UH | 1.04-108 | 10.4-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 26-29 | 180 |

| N30UH | 1.08-1.13 | 10.8-11.3 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 223-247 | 28-31 | 180 |

| N33UH | 1.13-1.17 | 11.3-11.7 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 247-271 | 31-34 | 180 |

| N35UH | 1.17-1.22 | 11.7-12.2 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 263-287 | 33-36 | 180 |

| N38UH | 1.22-1.25 | 12.2-12.5 | ≥876 | ≥11 | ≥1990 | ≥25 | 287-310 | 36-39 | 180 |

| N40UH | 1.25-1.28 | 12.5-12.8 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 302-326 | 38-41 | 180 |

| N42UH | 1.28-1.32 | 12.8-13.2 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 318-342 | 40-43 | 180 |

| N28EH | 1.04-1.08 | 10.4-10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 26-29 | 200 |

| N30EH | 1.08-1.13 | 10.8-11.3 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | 200 |

| N33EH | 1.13-1.17 | 11.3-11.7 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 247-271 | 31-34 | 200 |

| N35EH | 1.17-1.22 | 11.7-12.2 | ≥876 | ≥11 | ≥2388 | ≥30 | 263-287 | 33-36 | 200 |

| N38EH | 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥2388 | ≥30 | 287-310 | 36-39 | 200 |

| N40EH | 1.25-1.28 | 12.5-12.8 | ≥899 | ≥11.3 | ≥2388 | ≥30 | 302-326 | 38-41 | 200 |

| N28AH | 1.04-1.08 | 10.4-10.8 | ≥787 | ≥9.9 | ≥2624 | ≥33 | 207-231 | 26-29 | 230 |

| N30AH | 1.08-1.13 | 10.8-11.3 | ≥819 | ≥10.3 | ≥2624 | ≥33 | 223-247 | 28-31 | 230 |

| N33AH | 1.13-1.17 | 11.3-11.7 | ≥843 | ≥10.6 | ≥2624 | ≥33 | 247-271 | 31-34 | 230 |

| N35AH | 1.17-1.22 | 11.7-12.2 | ≥876 | ≥11 | ≥2624 | ≥33 | 263-287 | 33-36 | 230 |

| N38AH | 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥2624 | ≥33 | 287-310 | 36-39 | 230 |

3.Completely control on full manufacturing process by quality control dept and experienced engineers in each process.

FAQ:

1. Q:What information do I need to supply when I have a inquiry?

A: If you have any inquiry, please kindly advise the following items:

Dimensions or drawing with tolerances.

Material grade or magnetic properties.

Magnetic direction.

Surface coating(if necessary).

Quantity and delivery terms.

2. Q:What equipment do you have?

A: We have more than 100sets of cutting machines and grinding machines,and we found China Ningbo University R&D center in our plant, with advanced R&D equipment, such as Particle size analysis, Angler deviation tester, ICP, Hast Tester etc from Germany and Japan.

3. Q: What about OEM and ODM?

A: OEM and ODM Accept. We have our best designers, we can produce any design you wanted to meet your needs.

4. Q: What about the sample time and charge?

A: (1) 7-10 days if you want to customize your logo, charge according to your design

(2) 3-7 days for our existing samples for reference

5. Q: What about the delivery time of our products?

A: Fast Delivery when you choose the item and decide your design, we can produce it as fast as possible, and deliver it as quick and convenient as possible.

6. Q: Could you provide me the shortest lead time?

A: We have materials in our stock,if you really need, you can tell us and we will try our best to satisfy you.

7. Q: How to pay you?

A: T/T in advance(telegraphic transfer-bank order), for small order, or samples order, or shipment by air.

T/T, PayPal,Western Union cash - for small order or samples order.

Other payment: L/C,D/A,D/P,MoneyGra,Paypal or Escrow.

8. Q: Do you offer aftersales service ?

A: Of course, we accept any feedback about our Quality, Service, Market Feedback& Suggestion. And we'll do better.

9. Q: Could I pay a visit to your factory?

A: Yes, of course, if you need, we will help you visit our factory.